Page 1 of 1

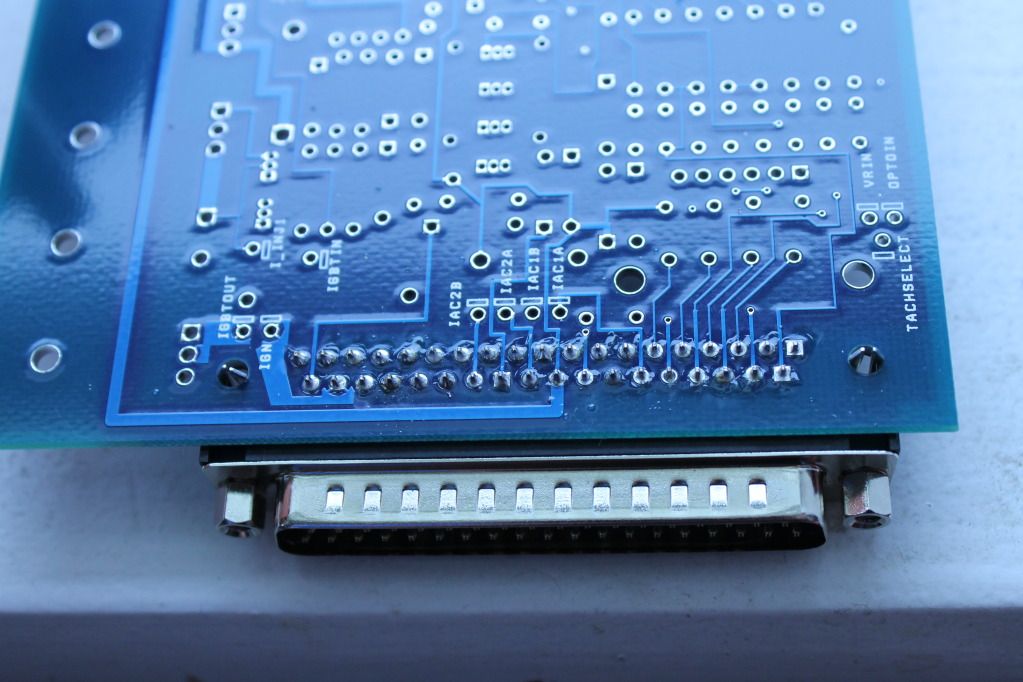

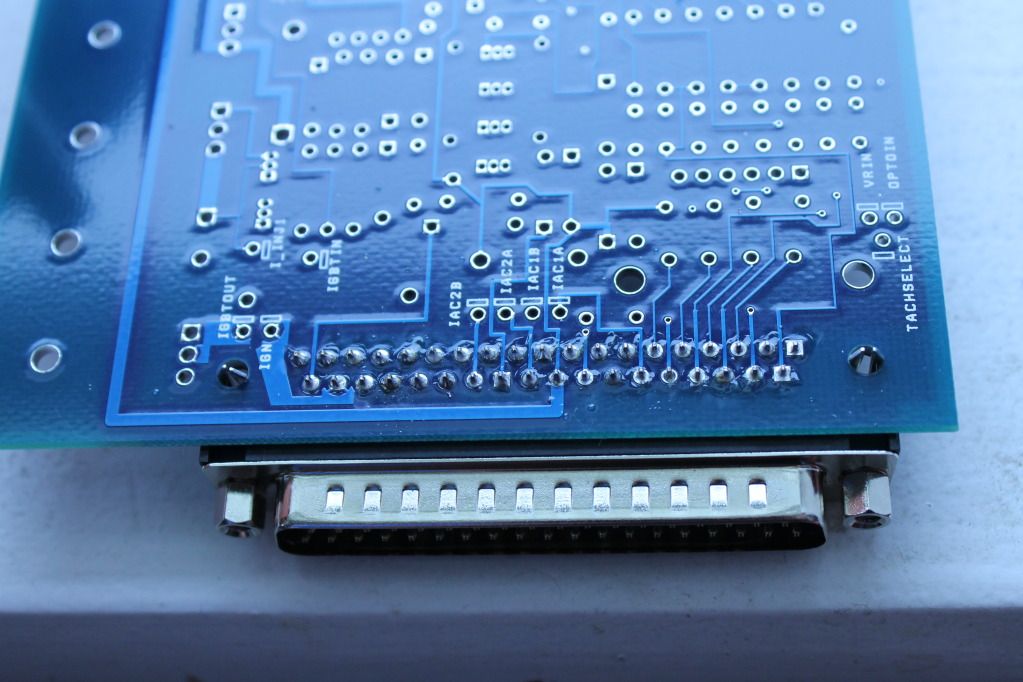

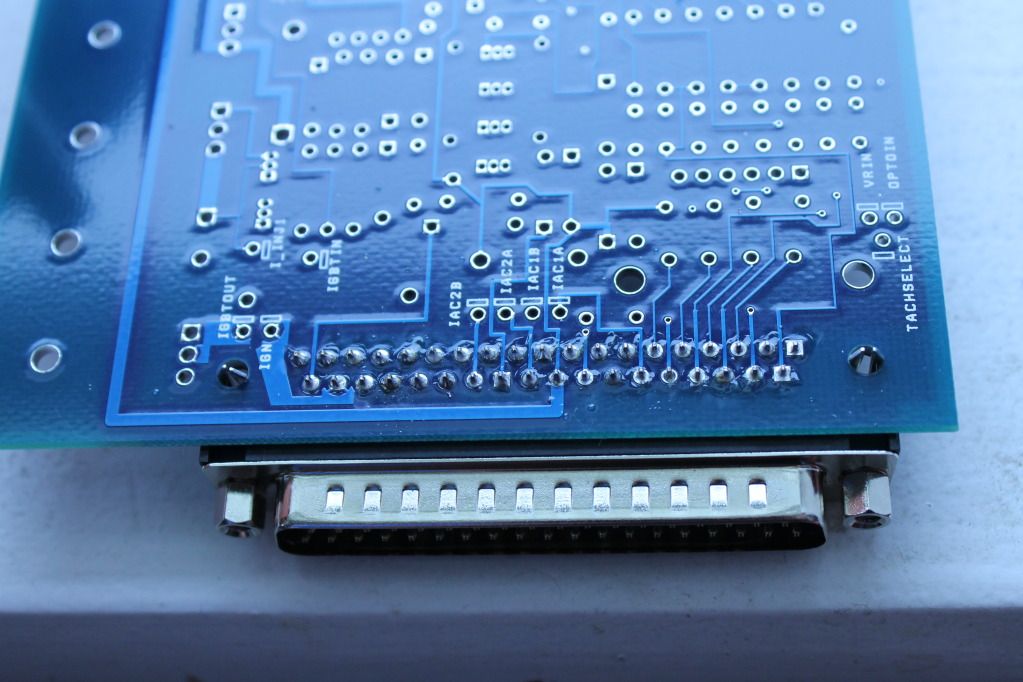

How is my soldering?

Posted: May 28th, 2012, 3:09 pm

by Ryan

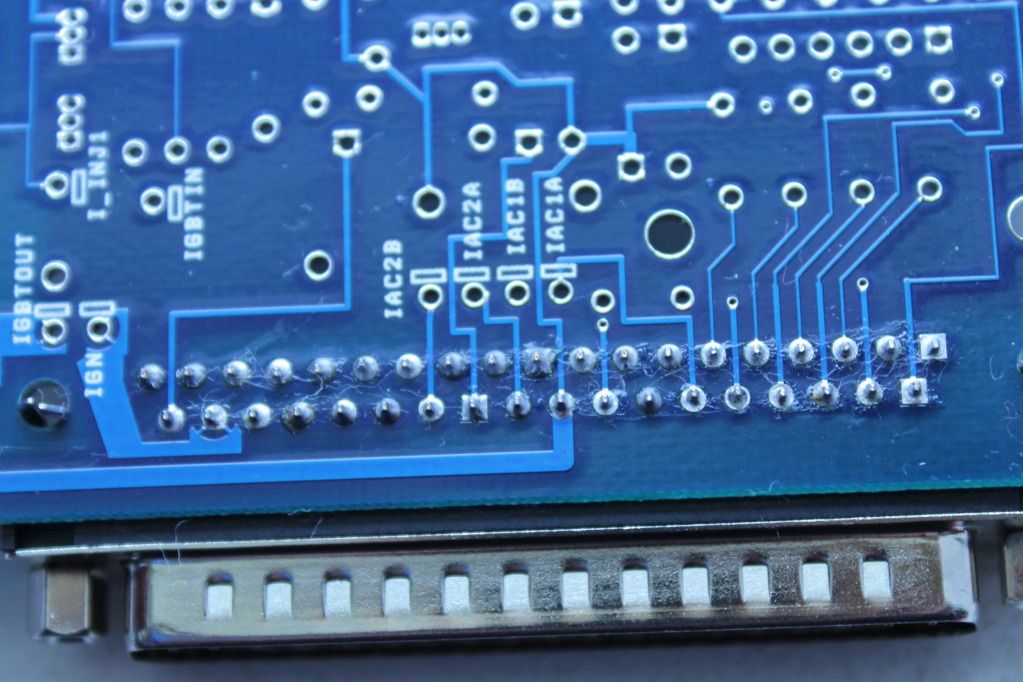

Although it says expressly in the MS assembly guide to not let MS be your first attempt at soldering, this is my first attempt to solder anything to a PCB.

I'm using a 20w pencil iron and a silver bearing solder (unsure of composition)

The main question I have, is if its supposed to 'cone' on both sides of the board or not? You can get it to work with an amount of solder, or twice that amount, it just flows through to the 'bottom'.

Also, I hear they use 'alcohol' to clean the flux off, but what sort of alcohol? Smirnoff? Grey Goose? Rubbing? Absinthe?

Re: How is my soldering?

Posted: May 28th, 2012, 3:21 pm

by Mi|<E

Try to use less heat if you can as you are starting to warp the board a bit. Yeah you

want cones on both sides.

The biggest thing to watch for is too much heat can lift off the circular contact on the board

then its a mess to fix.

Rubbing alcohol for the board, grey goose in your mouth - dont mix this up.

Re: How is my soldering?

Posted: May 28th, 2012, 3:25 pm

by Ryan

thanks for your input!

I'm pretty sure what you're seeing as 'warpage' is just excess flux on the board. I'll wipe it down with grey... no, wait, rubbing alcohol, and I'll snap another photo.

Re: How is my soldering?

Posted: May 28th, 2012, 3:25 pm

by Nd4SpdSe

Soldering looks clean, but I would say you need a tad more solder.

Not sure what you mean by conning on both sides of the board? It's it's conning on the other side of the board that we can't see, between the board and the DB37 connector, you shouldn't have any solder there at all. If the solder is leaking through to the otherside, I want to say you're using not enough heat since the heat is going down the lead too far and the soldering is following. I have a Weller station, and typically solder @ 650*F, and desolder at 750*F

Rubbing alcohol, you tend to burn your tongue licking the PCB when using the good stuff. Rubbing alcohol doesn't really (shouldn't) tempt you for ingestion.

You can get flux cleaner too, that works great.

Re: How is my soldering?

Posted: May 28th, 2012, 3:34 pm

by Ryan

From what I understand these connected have a sort of rivet through them that allows a cone on the other side too, a double sided PCB, such as the second one here:

http://www.antex.co.uk/images/betterfig5.jpg

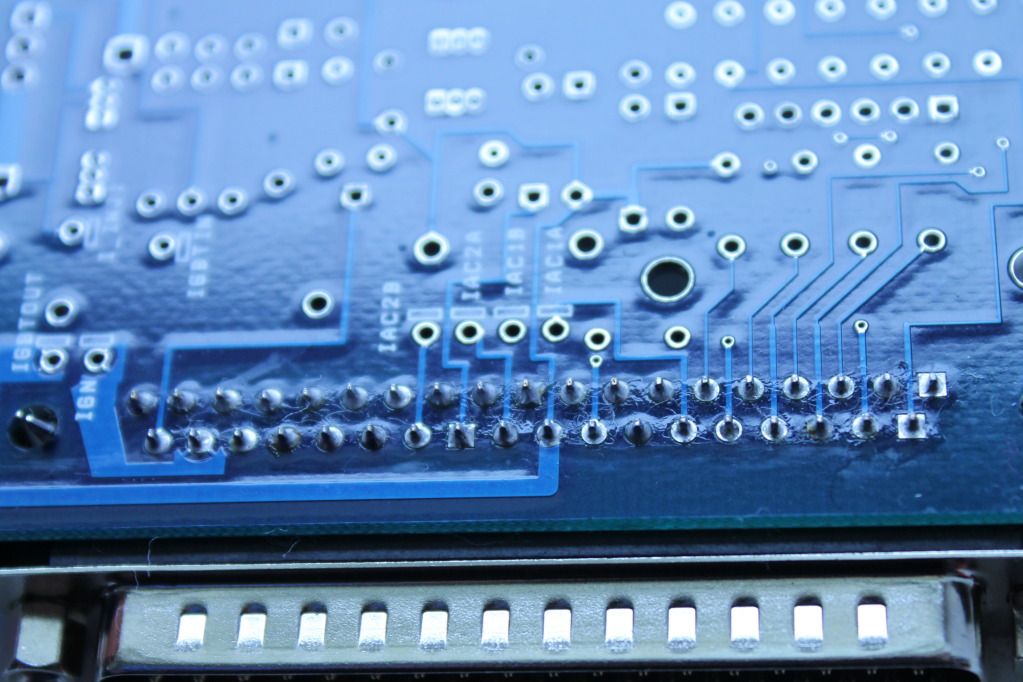

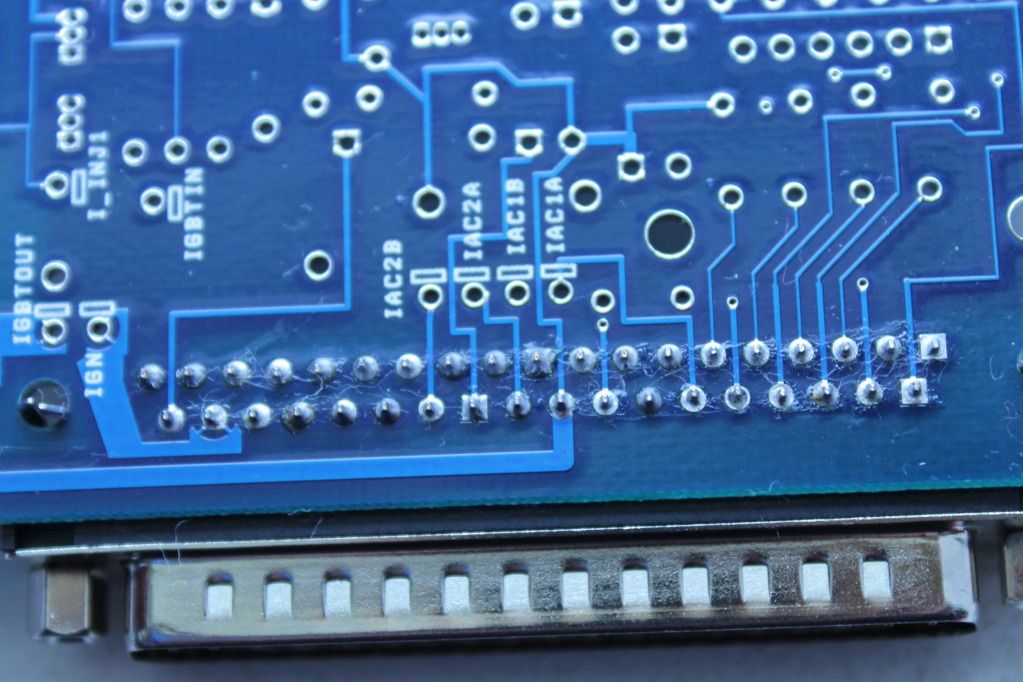

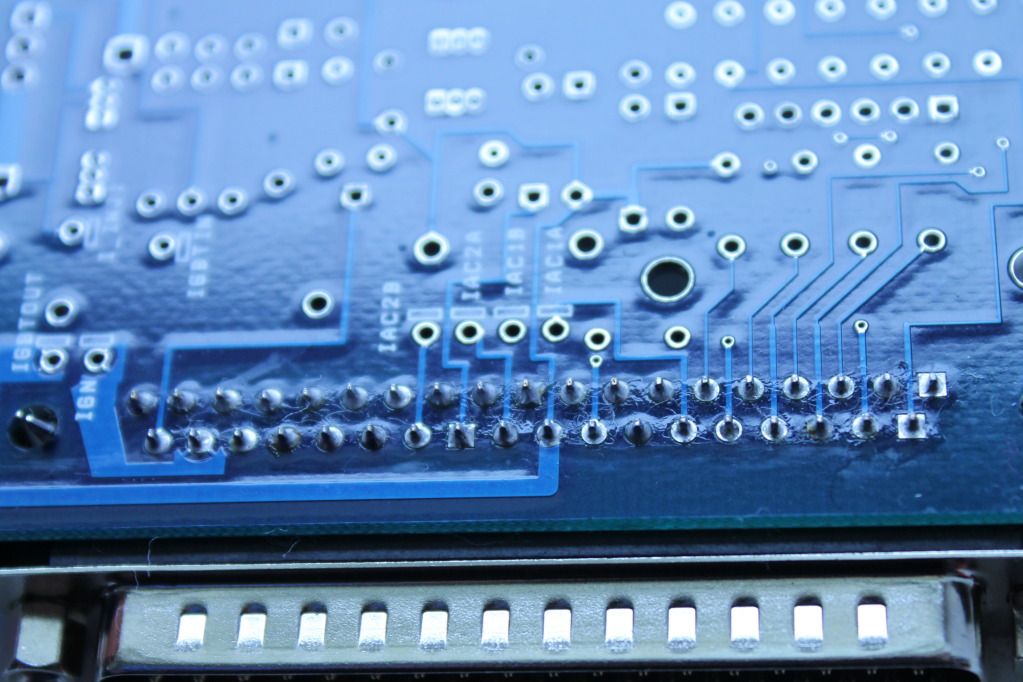

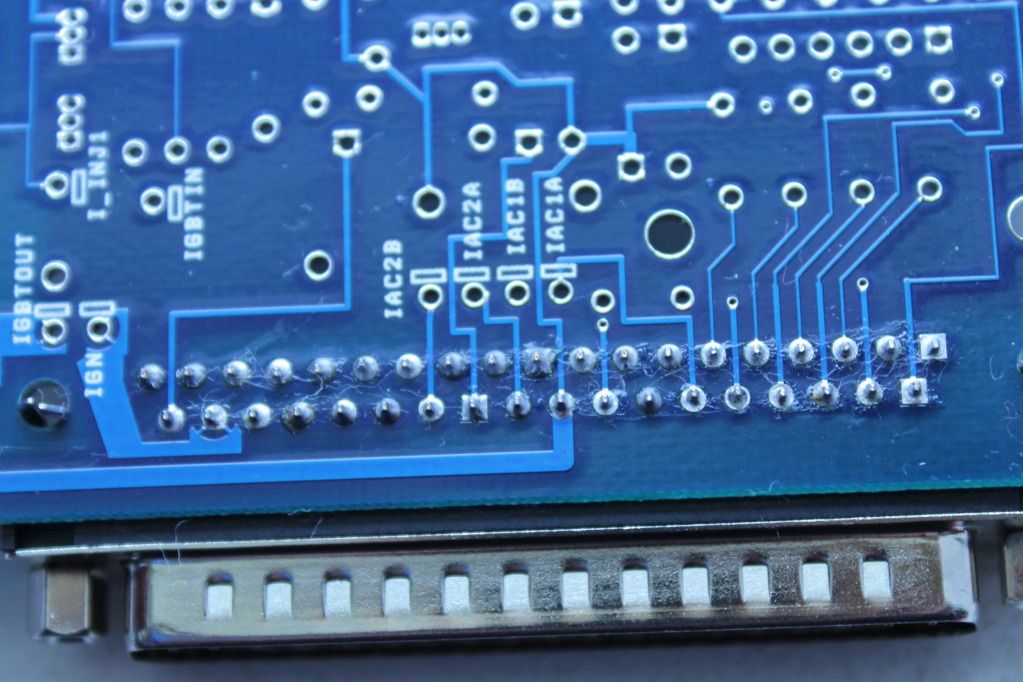

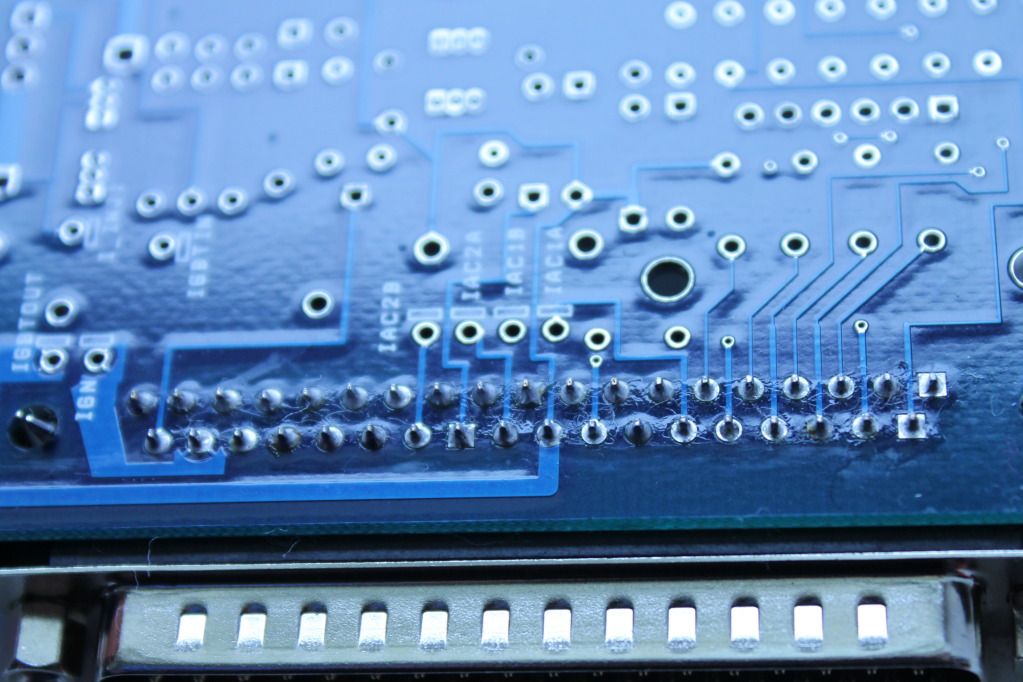

Here is post alcohol, excuse the fuzzies. I used the wrong sort of cloth

I'll have to get those out of there somehow.

The warpage around the holes seems to be the same around the unsoldered holes too.

Re: How is my soldering?

Posted: June 9th, 2012, 4:27 am

by WesleyK

Ryan wrote:From what I understand these connected have a sort of rivet through them that allows a cone on the other side too, a double sided PCB, such as the second one here:

http://www.antex.co.uk/images/betterfig5.jpg

Here is post alcohol, excuse the fuzzies. I used the wrong sort of cloth

I'll have to get those out of there somehow.

The warpage around the holes seems to be the same around the unsoldered holes too.

Those joints look clean, nothing to worry about. You could use a little more solder on a few pads, but if you keep it like this it will be fine. Just be carefull to not overheat a pad as the pad may come loose. You have a low power soldering iron so it can take long for some pads(with large copper areas attached) to heat up and the solder to melt, just be patient in these cases! If you can find a nice 40W-80W temperature controlled (something like 330C will be fine) soldering iron use you may consider using that one instead.

Those warps seems to be all over the PCB, seems to be a bad quality manufacturer

Also, who designed these PCBs? Damn.. looks like someone was drunk while designing..

Re: How is my soldering?

Posted: June 11th, 2012, 12:05 am

by Ryan

Bowling and Grippo, the same company that makes all of the Megasquirt PCB's.