Page 5 of 22

Re: Project Jay-Spec MX-326GS

Posted: March 16th, 2010, 12:41 am

by mikeinaus

what kind of paint are you using on everything? is it some special auto paint that wont chip?

ive been fallowing this build for the past few days and its awesome. i really like the work your doing on this car. keep it up.

Re: Project Jay-Spec MX-326GS

Posted: March 16th, 2010, 10:42 am

by IMACHU2

mikeinaus wrote:what kind of paint are you using on everything? is it some special auto paint that wont chip?

ive been fallowing this build for the past few days and its awesome. i really like the work your doing on this car. keep it up.

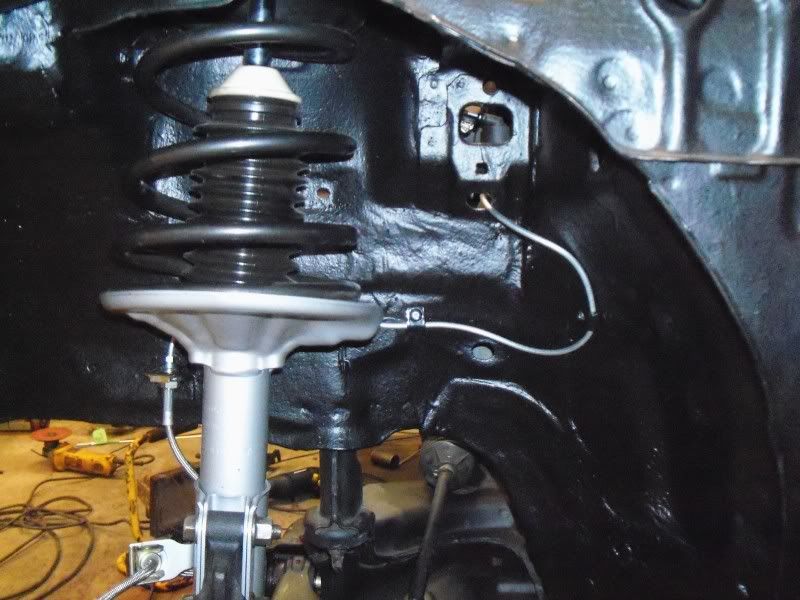

Well lots of different paint. The Calipers / rear rotor hats / caliper brackets are all brush painted with Dupli-color caliper paint. The bottom of the car was painted with No name Rust-Oleum / Tremclad flat black with a brush. The inner fenders have spray rubberized rocker guard on them (usually ment for rock chip protection under the trim line). The front rotors came that way (Cad plate). Everything flat black is just no-name Rust-Oleum / Tremclad flat black from a rattle spray can. Everything aluminum was painted with a generic rattle can Zinc Chromate Yellow Primer, then painted with no-name rattle can Rust-Oleum / Tremclad flat black. Nothin' too fancy

I used the same techniques on my last car it holds up really well. The key to a good paint job is in the prep. I spent 12 hours wire brushing the bottom of the floor. If you can eat off it it is ready for a paint thinner wipe down, grey primer, scuff with a brown 3M pad, wipe down with thinner, then paint

The wire brush cleans off all the dirt and flakey paint and it scatches everything which makes the new paint stick better. I usually clean everything with a paint prep or clean paint thinner and a clean rag before I paint it too.

Re: Project Jay-Spec MX-326GS

Posted: March 20th, 2010, 9:24 am

by bbunkerc397

You've got some serious time on your hands.

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 1:55 am

by IMACHU2

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 9:31 am

by Ryan

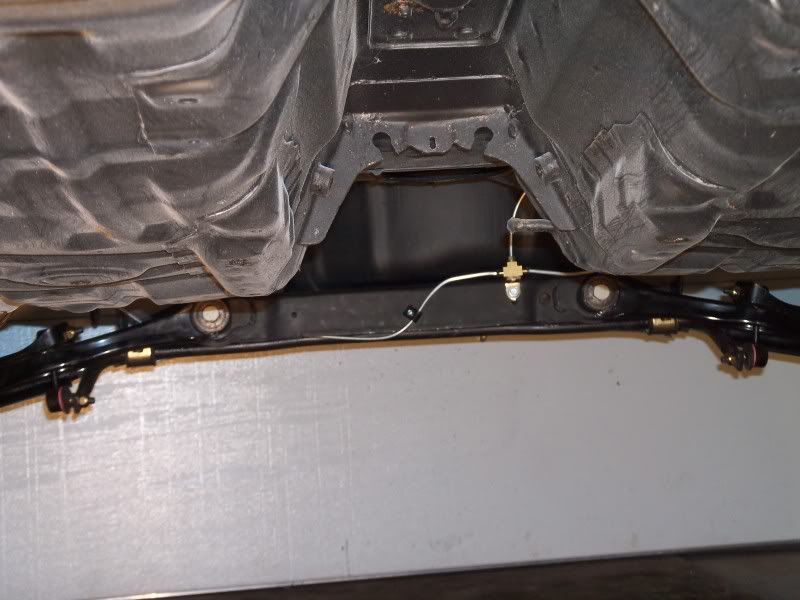

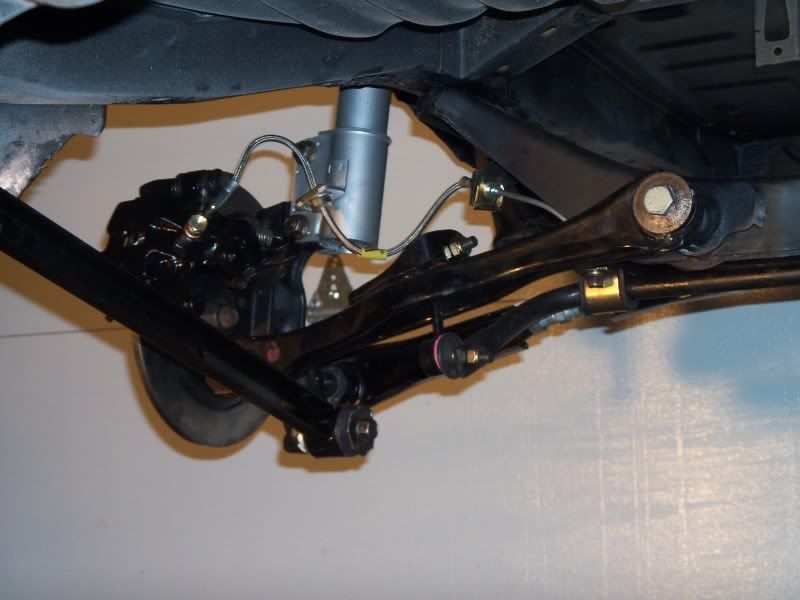

Don't you think that valve is a little far foreward? You'll have to be careful to to kick it every time you get in or out... it would be nice if it could move back a half foot, closer to the hatch popper.

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 10:35 am

by IMACHU2

I have short legs, so it will 6" from the front of the seat. It is located in the same place as in the Mustang. I "test drove" it in my daily driver 323 It appears to be out of harms way. (duct taped it in the hole in the floor and drove around the block) LOL. It is is a no step zone when exiting. The only problem now is I had to look under my daily driver 323 a few time to understand and see where potential spacial conflicts would be. It is really, really scary under there

(the carpet is a structural member).

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 4:02 pm

by PATDIESEL

Just a note- you should consider making all of your brake lines the same legnth from left to right sides. Otherwise you'll get pull from the steering every time you brake

On stock Mazda brake lines you'll find a coil of brake line on the shorter side to make up for the difference in legnth. Usually right on the inside of the fender before it penetrates is where I have seen the coil of tubing placed.

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 4:29 pm

by solo_ryder

Wow, you do some incredible work.. Everytime I see this WL it makes me happy seeing someone restore a 323 like this, with this level of detail. Good stuff!

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 7:27 pm

by fowljesse

Clothesline?! What kind of wierdo would put parts on their car that aren't even auto parts?

Oh, yeah.

Me.

I would have found a way to actually use the clothesline as a brake line

I have to agree; Nice work!

I can't wait to see videos of it in action!

Re: Project Jay-Spec MX-326GS

Posted: March 22nd, 2010, 11:52 pm

by IMACHU2

PATDIESEL wrote:

Just a note- you should consider making all of your brake lines the same legnth from left to right sides. Otherwise you'll get pull from the steering every time you brake

On stock Mazda brake lines you'll find a coil of brake line on the shorter side to make up for the difference in legnth. Usually right on the inside of the fender before it penetrates is where I have seen the coil of tubing placed.

A dude named Pascal would disagree LOL

Pascal's Law

Pascal's Law states that, because fluids are virtually non-compressible, any force applied to a closed hydraulic system will be felt equally and instantly throughout the entire system.

Why do brake lines have so many bends and loops?

You may think that the person who designed your brake lines was crazy, but all of those bends and loops have a purpose: They add flexibility.

Cars and trucks bend and flex as you drive. Many trucks have a frame that supports the body. The body is attached to the frame by rubber mounts, so there can be a lot of motion between the body and the frame. The master cylinder is attached to the body while some of the other brake components are attached to the frame. Also, when you step on the brake pedal, you flex the firewall of your car, moving the master cylinder but not the other components in the brakes.

A car is not always built with perfect accuracy. On one car the distance from the master cylinder to the anti-lock brake system pump will be slightly different from that on another. The extra flexibility added to the brake lines allows cars to be assembled even though they are slightly different from one another.

If the lines were short and straight, the motion of the car would eventually crack the brake lines; the continual flexing would fatigue the metal and eventually break it, just the way a spoon bent back and forth repeatedly will eventually break. By forming the brake line into a coil, the flexing in any one section is very small, and so puts almost no strain on the line.

Flow

While its true that flow would decrease pressure available at various distances from the source for things like water systems..the "flow" in a brake system is nil so the distances, number of elbows etc have no effect...pressure will equalize throughout the system. The only thing will be extra fluid in the system to take up extra length. Pressure in the closed hydraulic system will remain equal at all times. Your input/output force ratios will change when your input/output piston diameters change. The lines connecting to the pistons do not affect pressure.

Theory behind a proportioning valve:

At lower pressures, the prop valve effectively does nothing. At higher pressures, a piston separates the fluid at the inlet and outlet sides. No fluid flows through the valve. Therefore, the pressure locked into the system will remain constant at the preset (factory prop) or adjusted rate (as in an adjustable prop). Keep in mind the proportioning valve can be used to reduce brake line pressure, but will not increase it.

Re: Project Jay-Spec MX-326GS

Posted: March 23rd, 2010, 12:06 am

by _-Night-Shade-_

Genius. This guy knows his stuff

Re: Project Jay-Spec MX-326GS

Posted: March 23rd, 2010, 12:06 am

by IMACHU2

fowljesse wrote:Clothesline?! What kind of wierdo would put parts on their car that aren't even auto parts?

Oh, yeah.

Me.

I would have found a way to actually use the clothesline as a brake line

I have to agree; Nice work!

I can't wait to see videos of it in action!

I thought you would like that idea LOL

solo_ryder:Thanks. I am not looking to make a show car, just a car I can enjoy and tinker with without needing a tetanus shot and a de-greasing post tinker.

Re: Project Jay-Spec MX-326GS

Posted: March 23rd, 2010, 12:39 am

by wytbishop

I was going to say something about the transmission of hydraulic force but I figured I've been the Clavin around here too long.

Your car is lookng great. I wish I had a parts store of my own.

Re: Project Jay-Spec MX-326GS

Posted: March 23rd, 2010, 10:58 am

by IMACHU2

wytbishop wrote:I was going to say something about the transmission of hydraulic force but I figured I've been the Clavin around here too long.

Your car is lookng great. I wish I had a parts store of my own.

Me too LOL. I am the manager of a Speed Shop (not the owner). I does have its perks though.