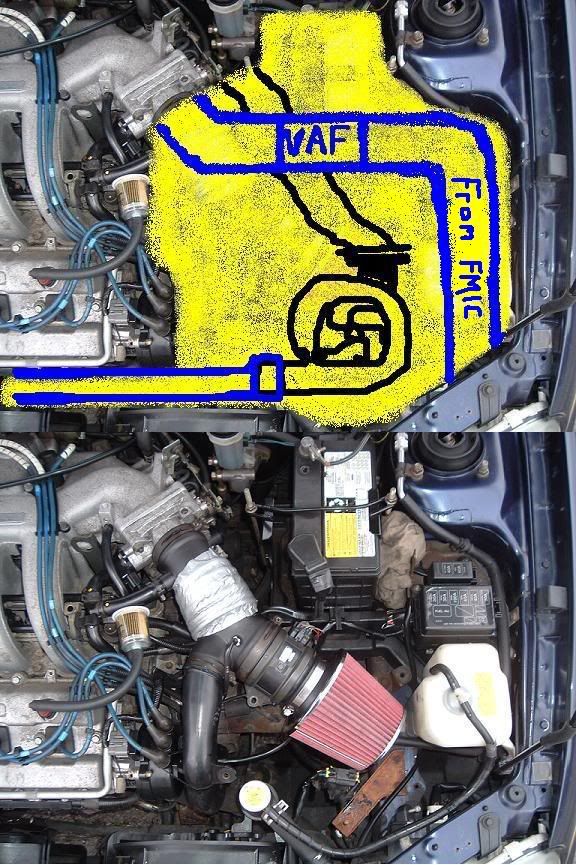

Reference pics... There's alot of space once those things are moved (easily)... I was thinkin of routing the outlet-side piping of the turbo down along that yellow strip between the head & rad, to one side of a FMIC... See where I'm goin with this yet...? The return side would come up right behind the drivers headlite and follow the blue-line to the VAF & TB... Exhaust would be routed strait down (obviously turning back to exit the system) in front of the tranny, while coming in from a custom design using the stock/aftermarket fr. mani joining the rear @ the rear and run it over and up the backside of the tranny... leaving only the filter side of the turbo, to which a custom 'RAM-AIR' hood/airbox setup could be utilized (see pic, notice the molded eyebrows!)... Or do turbos work better with the tube attached, creating the tunnel effect...? And what about the oil line, is it bad to run them vertically...?question for you turbo guys... can you mount a turbo vertically...? like with the intake side facing up, so theoretically (using the most common MX-3/P-GT/MX-6 method of mounting the turbo by the distrib/airbox) if you put just a filter on it, it would stick strait up through the hood...? Follow me? There's plenty of room on that front corner, especially with a battery/coolant-res relocation, to stuff a turbo in there

Just curious, might make routing exhaust easier...?

2nd one's abit rough, I know...

.

.